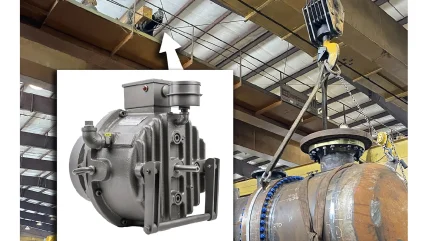

Force Control Industries announced that its MagnaShear motor brakes significantly enhance crane safety by eliminating the need for brake maintenance, adjustment, and repairs.

The MagnaShear crane brakes feature Force Control’s Oil-Shear technology, which offers a solution to the challenges of crane brake maintenance that often requires work at height.

By eliminating the maintenance works, the MagnaShear crane brakes not only enhance safety but also improve crane uptime and utility.

Their Oil-Shear technology transmits torque between lubricated surfaces, eliminating wear on friction surfaces and extending service life.

MagnaShear’s patented fluid recirculation system dissipates heat, addressing the common issue of heat buildup in dry braking systems.

The approach significantly increases service life and reduces the need for adjustments, elongating maintenance intervals.

MagnaShear brakes can be used in various industries, including anodising plants, foundries, and critical-line manufacturing plants.

The Oil-Shear technology provides a smooth, cushioned stop, reducing shock to the drive system and extending the service life of downstream components.

Unlike dry brakes, Oil-Shear technology uses a layer of automatic transmission fluid between the brake disc and drive plate.

As the fluid compresses, it shears, imparting torque and decelerating the rotating discs against stationary plates, preventing wear and the need for adjustments as in dry brakes.

The patented fluid recirculation system not only dissipates heat but also lubricates all components, further extending their service life.

Force Control is offering MagnaShear motor brakes in a wide range of motor sizes for various applications with spring set torque ratings from three to 1250 foot-pounds.

The brakes offer a maintenance-free operation, with a significantly longer service life.

MagnaShear features ‘quick mount’ capabilities for easy installation on NEMA frame sizes 56 to 449 and can be pre-mounted on a motor for severe duty applications.

Also, the motor brakes are completely enclosed to protect against outside contaminants, making them suitable for harsh and washdown environments.