The Overhead Alliance will better serve the three MHI (US Material Handling, Logistics & Supply Chain Association) industry groups CMAA, (Crane Manufacturers Association of America), MMA (Monorail Manufacturers Association) and HMI (Hoist Manufacturers Institute).

Krauth was born in the Minnesota region. He studied marketing and grew up around structural steel and cranes as his father was GM for a steel fabrication shop. After pursuing a career in retail management, he decided to switch focus and move into cranes as a salesman and eventually worked his way up into his current role at the company today.

The Overhead Alliance is a work in progress and will meet once a quarter to drum up support for members and to bring in changes and welcome more vice presidents from each of the MHI industry verticals.

OCH: Dustin what drives you as an industry leader?

DK: I think knowing that I’m making a difference is a major driving force. At TC/A I’m doing my part to grow a 100-year-old Patented Track company into a full-service solutions provider, and watching these changes come into fruition is really what drives me to keep making meaningful changes within the company. Thanks to MHI and my work with the Overhead Alliance, I also get to do that on a broader scale. I’m working with a great team there, helping to grow an entire industry, not just my company.

Our now president Jerry Eischens was the liaison for me when I came on board. He introduced me to MHI. I was not only new to the job but new to the industry but right out of the gate was introduced to the MHI Marketing committees. Coming into an industry like this, there is so much to learn it is like drinking water from a Firehouse hose. There’s just so much getting thrown at you constantly. I’m someone who loves a challenge. So, for me, it was enjoyable to get in and push through and see the other side, so to speak.

OCH: What is your biggest business inspiration?

DK: It’s similar to what drives me as a person, just plain working hard and doing great work. I think Steve Jobs said it best. Your work is going to fill a large part of your life, and the only way to be truly satisfied is to do what you believe is great work. For me TCA has been such a great fit in that it’s a hard-working company and constantly working to improve the product line for our dealer network and in turn our end users.

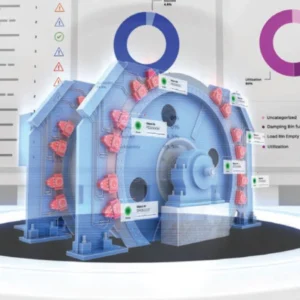

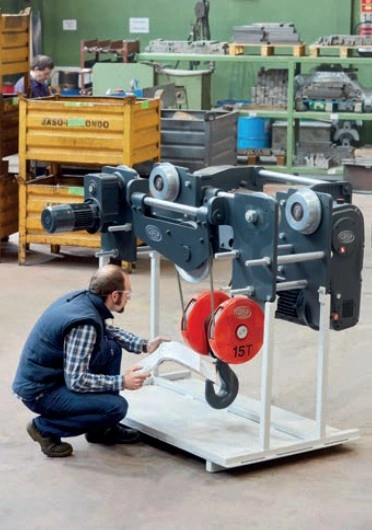

We started as a patented track company 100 years ago and really only had one product line for 95 of them. I joined the team at the perfect time as TC/A was in the process of making a lot of changes. Since 2019, TC/A has added our SPANMASTER workstation cranes line, top running structural/box girder cranes, and are now the sole distributor of JASO Industrial Cranes product lines here in the states. In the five years since I started here we have transitioned from just a patented track company to a full on Overhead Lifting Solutions Provider.

OCH: What is your business philosophy?

DK: I cut my teeth in customer service and coming from a marketing background, that’s the bread and butter of marketing. So definitely my philosophy is customer driven.

From my days of customer service to my current role, it all starts with serving the customer. This is even more challenging in my current role as we have very little direct interaction with our end users as our dealer network are our direct customers. I depend on the knowledge and capabilities of my dealers to pass those values on to our end users and customers. That’s another reason why it’s a great fit here. At TCA we have five core values, and the first one is customer driven, so they share the same top value as I do.

The other four are training and education, fiscally responsible, continuous improvement and valued partner. The valued partner value works closely with being customer driven. We have 300+ dealers right now and are one of only a few manufacturers left that will never bypass our dealers to sell direct to an end user. We depend on our dealers to be our local, “boots on the ground” and because of that would never undermine our relationship.

I have a team of 10 including inside sales, parts, admin and regional sales managers. Our inside sales, parts, and admins handle the quoting and work closely with our dealer to make sure we are delivering what the customer is looking for. Our regional sales managers are regularly traveling and meeting with dealers to make sure we are following through on what we are promising. Except for a couple of remote people, we are all here in our Elk River office.

OCH: How did you enter this business?

DK: I was at a pivotal point in my life. As I mentioned, I spent 15 years in retail management, as a general manager trainer. I trained managers for a local convenience store chain, but I didn’t get to use a lot of my skillset in doing that and felt stuck in the realm. I left that position and was working as a consultant when a role became available at TC/American. I was familiar with the current president Jeff Palkovic, and knew him as a down to earth, jeans and T-shirt kind of guy. This was definitely someone I would enjoy working for. Once hired, I started in a role that was part time marketing, part time inside sales and eventually worked my way up to where I am today.

It’s funny, I didn’t think about my father working in the business until I stepped foot in a shop again. Being in an industrial setting brought back that nostalgia. Being able to have those conversations with my dad as well, he’s obviously long retired, but being in a similar realm has been awesome.

I went to the University of Wisconsin superior. I was born in North Minnesota what’s called the Iron range of Minnesota, known as the mining belt. And then that’s where I went to university, which was an hour-and-a-half south of there.

OCH: Tell us about your success stories

DK: I look at where I am currently as my biggest success story. Being brought on as a marketing guy and being promoted into different departments. One of my mottos in life is ‘fill the vacuum’. And that’s how I’ve found success – meaning, if you see something that’s not consistently being done by one single person and you have the time to do it, just do it. And by doing that, I moved closer into the sales department and then further into the leadership department just being that vacuum filler, so to speak. And I preach that to the people that work for me as well. Encouraging them that if you have the time to do it, take on that extra task.

My other success story is obviously MHI. I work with a small group of people bringing together, CMAA, HMI and MMA. The marketing team has been a bit behind the scenes so getting that vote from other membership companies to act as co chair on the Overhead Alliance with Laura seems like a great success.

Another success story just being on the team that has worked on bringing TC/A and JASO together. I work very closely with JASO in Spain and am the main day-to-day contact. They’re a big brand in Europe, but they’ve never really had a presence here outside of large process cranes in the steel industry. I would consider myself an integral part of that success.

OCH: Tell us about your failures and how you overcame any challenges.

DK: I would say the time I spent before coming into the crane industry. When I left my previous world and made the decision to go out on my own. I started a consulting firm doing marketing and business development for about a yearand- a- half. While financially lucrative, ultimately it was not what I was looking for. I needed more of a professional purpose, something to sink my teeth into and be a part of, and TC/American seemed like the right fit. I could have continued on my own but decided to hand off my clients and attempted going it alone as a “failure” sort of speak.

OCH: What do you like about this business?

DK: As cliches as it sounds, I love the crane world. It’s an extremely large industry, but an extremely small community. There’re hundreds of manufacturers, thousands of businesses. But I have quickly gained contacts that so many companies are a part of, so many small and large communities of people throughout the industry. I don’t know any other industry like it. I was told when I first started here that once you join the crane world, you’ll never leave. And I’ve heard that in other industries before, but it is definitely the case here. I don’t ever plan on leaving this realm. It’s just an ever-changing industry and every day is a new challenge and that’s what drives me.

OCH: What do you dislike about this business?

DK: Lack of knowledge for the stakeholders. There’s just a lack of information out there for end users and knowledge, even for someone new coming into the industry. You have to kind of depend on internal knowledge getting passed down by word of mouth within what I would call the elders of the company. A lot of my training was done by them physically teaching me. So being part of the Overhead Alliance in MHI is so important to me because that’s a big part of what we do, helping to educate the end users and not only on the products that are available to them but on safety and allowing them to make the best decision according to what they need.

OCH: What makes your company unique?

DK: We have a great history of serving the material handling world and literally doing our part to build the world as we know it today. But what’s unique about TC/A is that we’ve been able to successfully pivot from a 100-year-old single product patented track company to a full stack solutions provider. For example, we have dropped four new product lines in the last five years and all of them are seeing success. (SPANMASTER Workstation Cranes, JASO Crane kits, Top Running Cranes, and Box Girder Fabrication) I was lucky enough to stumble upon a company that not only shares my values, but was also at a similar pivotal point and looking for a big change.

OCH: What is your view on the future of the overhead cranes business?

DK: The material handling world is moving into ‘doing more with less’, so we’re seeing much more long span cranes, large capacity cranes. Where we would see two or three 10-ton cranes, with 30-foot spans, we’re now seeing 100-foot span cranes from 30 to 70 tons, which was great timing for us because we’ve been moving into that product line. The other big change is automation. As I mentioned before patent track was our core product line for 100 years but that has regressed over the years, and it has been a shrinking market as people move to more structural beams based on the application. Not everyone shares my enthusiasm, but personally I see that industry returning as we move into more automation. When it comes to an automated system that will run designated travel paths close to 24 hours a day, there is no better product available than patented track… So, I definitely see a trend in that direction where we see what is essentially one of the oldest products designed for material handling coming back into “the fold”.

The speed at which new technology is adapted for automation doesn’t surprise. We’re at a point of exponential growth when it comes to technology. Even in my lifetime, I have seen more advancements in technology than my parents and grandparents’ generation combined and I’m very much looking forward to seeing what happens next when it comes to overhead lifting, even carbon fiber cranes (doubtful) for example.

It’s very interesting and one of the reasons why I love being in this industry because it is at the forefront of change. Sustainability will also play a huge part in that in the future. It’s definitely not an industry that’s going to go away, it’s something that will always be utilised and is the backbone of industrial manufacturing.

5 tips for success

- Take ownership of what you do. it doesn’t matter what your actual role is in the company. If it’s not your company, then you’re in the right position.

- You’re nothing without your team. I’ve spent most of my life managing teams but without a strong team any leaders are doomed.

- There’s no substitute for hard work, you have to grind to succeed.

- Fill the vacuum, so if there’s a new or existing task that is not consistently getting done by one person on the team, take ownership of it. It shows initiative and allows opportunities to arise within that company.

- Finally, know your audience. one of the major drivers of success is communication, it’s a big driver. From the interview process to your retirement party, your professional relationships are built on communication, so honing your communication skills and the ability to read people is very important to succeeding professionally.

Company profile

Twin City Monorail and American Monorail merged to form TC/American in 1990. Then in 2017 TC/American Crane Company was formed from American Monorail, Twin City Monorail, and Spanmaster.

TC/American is one of the foremost providers of material handling equipment in the United States. With nearly a century of experience, in the overhead crane and monorail industry, TC/A started as Patented Track company and has grown to a full stack material handling solutions provider.

Personal life

Krauth married his childhood sweetheart Holly and they have two daughters: Aliyah (left) aged 25 and Gracie (right)15, training to be a pilot and actress respectively. In his spare time, Krauth follows in his father’s footsteps as a waterfowl hunter and enjoys playing golf.