Eldon James Corporation, which manufactures a proprietary line of 6000+ fittings, SeriesLock Quick Disconnects and a complimentary line of PVC-free tubing, has expanded substantially in the last few years as a US supplier of critical components used by vaccine manufacturers, pharmaceutical and medical device companies, laboratory, industrial, and automotive manufacturers.

Thanks to its rapid growth, the company contacted Wazee Crane and R&M to improve its heavy lifting machinery, to maximize its horizontal hook approach and hook height, for its cleanroom facilities, while maintaining safety and efficiency.

“Since 1987, Eldon James has relied on cranes to lift and move its heaviest components. We would not be able to function nearly as efficiently without a crane to do the heavy lifting. We are continually looking for ways to create a safer and more efficient environment, so we turned to Wazee Crane and R&M to help us improve in both areas,” said Seth Merrill, director, marketing, Eldon James.

Eldon James Corporation, based in Denver, Colorado, started construction on an expansion project in 2021 and now has an additional factory in nearby Fort Collins, where it serves a broad spectrum of domestic and international market sectors such as transportation, automotive, medical, water purification and industrial.

Fort Collins was the sixth expansion for the company in its 34-year history and is next to its WilMarc facility, which manufacturers medical devices made from PVC-Free plastic materials. Hospitals are actively seeking medical devices that are free of harmful plastics like PVC and made in the USA.

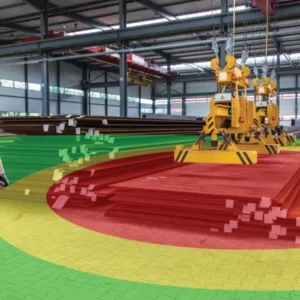

The cleanroom facilities focus on manufacturing products for the life sciences, bioprocess, biomedical, pharmaceutical and similar critical-use applications and it needs overhead cranes to lift injection molding machines that contain 2,000 lb. steel and aluminum part molds.

These molds are moved up to 10 times a day between the machines and the maintenance rooms where they are looked after.

Based in Broomfield, Colorado, Wazee Crane has been manufacturing and supplying cranes for more than a century, producing over 5,000 cranes during that time. The company also maintains a complete crane parts and crane service department equipped with trained crane service technicians who are on call 24-hours a day.

Wazee Crane installed overhead bridge cranes with a minimum 2,000 lb lifting capability, fitted with Spacemaster hoists from R&M Materials Handling. R&M's Spacemaster SX wire rope hoist features a large drum diameter that creates near true vertical lift, and its frame design allows closer end approaches than other hoists on the market. Standard electric wire rope hoist configurations include normal headroom, low headroom and double girder designs.

An innovative hoist design provides the best headroom in the industry while minimizing hook drift and maximizing end approaches. Users benefit from better floor coverage and easier operation of the equipment. Standard inverter controls on the trolley reduce load swing and minimize brake wear.

“R&M produces compact and economical cranes which were ideal for this application. The customer needed to maximize horizontal hook approach and hook height – Spacemaster was a perfect fit for this application,” said Steve Andrews, General Manager, Wazee Crane. Merrill added: “Safety and efficiency are our two main factors for selecting Wazee and R&M. We know the entire process, from ordering and installation to maintenance and repair, will be handled quickly and professionally.

“The overhead cranes that Wazee fabricated with R&M’s hoists have been an ideal marriage for our needs. Wazee has qualified regional repair personnel, so we know that should there be an issue, our production won't be affected by the same amount of downtime as if we had to fly a team in from an international location.”