To better represent its commitment to support the automation of all material handling equipment MHI’s Electrifications and Controls Manufacturers Association (ECMA) was recently rebranded as the Automation Controls and Electrification Association (ACE).

This is more than just a name change, it is reflective of rapid changes that the industrial world has been going through, Jason Looman, president of Scanreco North America and chair of ACE, pointed out. He has a unique perspective about this recent name change given that he had also been the first chairperson of ECMA when it was formed through the merger of several other trade associations in 2001.

While it was originally formed to exclusively represent companies involved with supplying below-the- hook devices, radio controls and electrification systems for cranes – particularly overhead cranes – Looman said its goal was to eventually expand beyond cranes. This, he said, made a lot of sense given that many of its members were also involved in other aspects of the material handling industry. ECMA was at a crossroads given that while they were looking to not only write specifications for the crane industry but other material handling sectors, it was met with some resistance.

Nevertheless, Looman noted that in recent years the material handling industry has been changing.

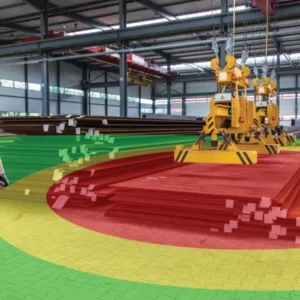

“Overhead cranes no longer exist on their own in factories,” he observed. “Companies are increasingly looking to integrate their different pieces of equipment – to have them talk with each other and work in synch.”

Because of this, by the time that Looman was re-elected chairman in 2019, the ECMA decided to change what it was doing, and to attract a new set of members, beyond those that are involved with who are involved with below-the-hook devices and electrical controls – more component, sensor, drive and motors suppliers from “the automation world.”

Given that a lot of people have been doing different things in different ways to try to solve their problems, Looman said the ECMA realized that there was an opportunity to form an association that will help get all the suppliers in one room together to come up with a solution. That, he said, includes suppliers of various types of material handling equipment represented by the MHI, including overhead cranes, automated guided vehicles, conveyors and others.

“We realized after attracting a number of key new members, such as Murrelektronik and Bosch Rexroth, we needed to rebrand ourselves to make it clear that we weren’t just an association focusing on overhead cranes anymore, but that now we were about automation,” Looman said, adding that he believes that the ACE name (which was officially launched during MHI’s fall meeting in October) is a good brand for what ECMA is now focused upon.

“This rebranding has been the best thing for us,” Looman declared, noting that it is a good way for the association to bring in new groups serving different parts of the material handling market, including certain longtime MHI members, such as Mitsubishi Electric, who, while being part of its solutions committee hadn’t previously been part of the ECMA. But now with the rebranding they had help to write and educate the market about certain new specifications being developed by ACE, which is looking to becoming the premiere authority on automation.

It is also expected to enable the association to double its membership. In fact, Looman said that ACE is expecting to bring in at least another five or six members just this year.

The rebranding isn’t expected to change the association’s impact upon the overhead crane market. “We are still planning to draft and update the specifications that we have for wireless controls as well as to help manufacturers to expand the features of their cranes,” Looman said, including their weight sensors and camera systems. Also, he noted that companies are increasingly looking to replace manual or remote controls that require human involvement with automated guidance systems. Looman said that ACE is considering developing more specifications for overhead cranes. He noted that currently North America is behind Europe in its specifications for crane stop functions, including the ratings required for that and having redundancies in place to stop the equipment. “ACE is currently looking at writing a white paper on the possibility of adding such specifications for North American crane manufacturers as well,” he noted.

Meanwhile ACE is looking to also expand the specifications for other material handling equipment including automated vehicles and conveyor systems, as well as doing so for certain general plant controls. “We are currently putting white papers together for that,” Looman said, noting that it will take a while – at least two years – to get American National Standards Institute (ANSI) specifications in place.

Looman said that the group’s existing membership – especially companies that are also members of other trade associations and who don’t just sell their products to overhead crane manufacturers – have be very receptive to this change. “They want us to do more and to grow our membership given that a rising tide raises all ships,” he said, explaining, “The more that we do, the better it is for them as well. Everyone wants to be part of a growing organization.”

ACE’s focus will likely continue to evolve, Looman said, noting that the group is currently meeting to develop what its strategy will be for the next two years, including what new areas upon which it could potentially focus.

“What we want is for ACE to be a safe place to discuss the automation push and how that could achieved the right way, the safe way,” Looman explained. He observed that right now there are many things that could be done just using today’s technologies, “But the question is whether that is the right thing to do. We need to get all the people developing these technologies to sit in a room with their competitors and to discuss what the standards for the future should be, especially those relating to the material handling world.”

While, in doing this, ACE will be continuing to diversify its membership base, Looman stressed that in doing so it won’t be going away from the overhead crane world. “We are looking to become an authority on automation in general while continuing the work that we have been doing for the overhead crane industry.