Daniel Beilfuss, GM of Columbus McKinnon Corporation’s (CMCO) Automation Division, which includes the company’s Magnetek brand, is celebrating his silver anniversary with the company this year and started his two-year tenure as president of the US Material Handling Industry (MHI) Crane Manufacturers Association of America (CMAA), in January. Here, we catch up with Beilfuss to find out what drives him to succeed.

OCH: Daniel, what drives you as an industry leader?

DB: I really enjoy helping customers win. I like solving problems, and helping clients understand what their issues are, what they're trying to overcome, and how to make them more productive by improving their processes through the equipment and services that we provide. We want to provide new ways of thinking about what they're doing, and help them to keep their operations running safely, efficiently and productively. If they win, we win.

Within the world of automation, when you automate processes, you're adding additional safety features which means instead of relying on one person to make sure they are following the right procedures and being safe in their operations, you can put things in place that makes them more efficient and their facilities and operations safer. As a result, they experience more throughput and productivity, which often drives future projects and repeat business.

To me, advancements in technology are exciting. When I look back 15 years ago, we had to convince people to invest in technology, but they were hesitant to do so at the time. Manufacturers couldn’t see how it would benefit their business and they didn’t know how to use it. But now, we have reached a point where you're almost expected to have some form of automation. And if you don't, you're going to get left behind and this is only going to continue to accelerate going forward.

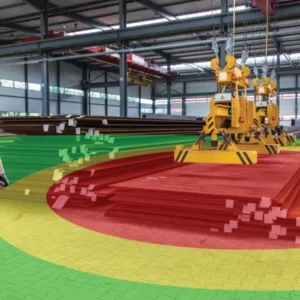

We continue to develop our Magnetek-brand motor and radio controls, with more value-added technology so the customer can get more analytics and diagnostic information. We have also developed standard off-the-shelf automation-type products for collision avoidance. No-Fly Zone Systems to pre-programme and map out the operation of a crane through a facility for safe operation. Anti-sway control has been around for many years, but it is still underutilised in the industry today.

OCH: What is your biggest business inspiration?

DB: Again, it ties in with helping customers win. I feel good at the end of the day if we can help to solve a problem and the customer puts their trust in us to provide a solution for them. Developing trust is extremely important to me. So much of what we do is custom-made for a specific application. We have a team of engineers that understand what the problems are, and what we need to resolve. We work together with our customer, it’s not just about selling them a product, but actually partnering with them to come up with an answer and then designing and developing a custom solution.

OCH: What is your business philosophy?

DB: Take care of the customer and they will take care of you, understand their needs, listen to what they have to say. Listen to the issues they might have, what they're trying to resolve. Don't come into it thinking you know it all. It’s essential to develop trust, a partnership, and a relationship, so even when things go south, because they do and they will, you can recover from that together and still find a path forward.

A lot of issues today revolve around safety and how to take the operator out of harm's way because a lot of these pieces of equipment that they're lifting, can include anything from molten steel to hot ingots or product that is transferred through a series of tanks, acid baths and the operator is working alongside that crane next to the production line. We want to understand how to make that a more streamlined and safer operation for the employee, the business, and the company, as well as creating more consistency with the products they're producing.

OCH: Why and how did you enter this business?

DB: I studied electrical engineering at Marquette University in Milwaukee, WI, and then went on to the University of Wisconsin-Whitewater for my MBA (Master of Business Administration). I love math and science and my dad was a tool and die maker for GE (General Electric). He worked a lot with engineers and always spoke highly of the design aspect. He’s one of the most talented people I know from being able to design a solution and actually build it. And that really inspired me to go into engineering.

After graduating from Marquette University, I went to work for a very large crane builder in the Milwaukee, WI area, Pawling & Harnischfeger (P&H), which was the predominant crane builder in the US at the time. Here, I started as an engineer, designing control systems and automation for overhead cranes.

I eventually left to join Magnetek, which was acquired by Columbus McKinnon in 2015 and I have been here for 25 years this year, and general manager for one year. I am in charge of the Automation Division, which includes Magnetek digital power and motion control solutions.

In my role at CMAA (the Crane Manufacturers Association of America) I started my tenure as president in January. Prior to that, I was vice president for two years. And I've been involved in the Engineering Committee as vice president for two years and assistant vice president for two years before that. So I've had two, four year stints of leadership within the CMAA organisation.

OCH: Tell us about your success stories?

DB: We did a big project with Hoover Dam about eight years ago. The Magnetek Material Handling team spent time working inside the Hoover Dam’s concrete structure alongside Precision Crane & Hoist Services of Nevada to modernise the facility’s aging AC static crane controls with state-of-the-art control technology developed by Magnetek.

The Hoover Dam has two power plant wings, one located in Nevada and one located in Arizona. Each wing is 650ft long and rises nearly 300ft above the foundation of the power plant. Two 300-ton cranes are located inside each power plant wing and are used to move and maintain 17 vertical hydraulic turbines housed within the wings.

The Hoover Dam Power Plant, one of the US’s largest hydroelectric installations, generates approximately four billion kilowatt-hours of hydroelectric power on average each year, enough to serve 1.3 million people in Arizona, Nevada, and California.

Magnetek controls were retrofitted on each of the four 300-ton cranes over a seven-month period. The new crane control systems utilise Magnetek’s technologically advanced drives and radio controls, providing crane operators at the Hoover Dam Power Plant with improved productivity, safety, and reliability.

OCH: Tell us about your failures and how you overcame any challenges?

DB: I’m proud to say we’ve had a lot more successes than failures and even when some of the jobs we take on are more difficult, we can turn them into a success over time.

When projects become extra challenging, we have to work our hardest to fix them and figure out what happened. My one word of advice is, always be accountable. If it doesn't work, admit it, identify the problem quickly and figure out a solution going forward. There's no sense in trying to point fingers at whose fault it might be or where the problem lies. We've got a job to do, and we've got to take care of it.

It's always good to be accountable and work together to resolve challenging situations, because at the end of the day you can still win that customer over. I won't name a specific example, but I will say when we have encountered a problem and the customer knows we stuck with it until it was resolved, we often get another opportunity with them in the future. That is the win right there.

OCH: What do you like about this business?

DB: I learn something new every day. There are exciting times ahead in the crane industry as the advancement of technology continues at a very rapid pace. Once upon a time it was difficult to sell new technology into this business but now it's almost expected to continue to evolve and move forward.

The biggest change I see is acceptance of the different technologies that are out there. The crane business sometimes seemed to lag behind when it came to technology. But nowadays people are using their phones to access information from home and to see what's going on with their crane. That capability continues to advance today.

OCH: And what do you dislike?

DB: I've been involved in this industry for over 25 years. It's continually changing but the one thing I disliked early on was how ‘old school’ it felt, slow to accept and adapt to new technologies and new ways of thinking. But over the past 10 years, we've seen a rapid change. And the competition that's out there, and the technology that's out there, everybody is coming out and really thinking about new ways of doing things and that's what's exciting.

OCH: What makes your company unique?

DB: With Columbus McKinnon, we build hoist products. Then the Magnetek control products we build are applied to the hoist products. Columbus McKinnon has recently started getting involved in other forms of material handling in conveyor systems. What is unique about us as a company is that we’re taking a harder focus on technology and how to expand technology throughout the material handling world, both within our own products and what we sell to others. We understand that automation is the future. We are looking at how we can apply the t echnologies we're developing for cranes and conveyors into other areas for the benefit of the overall material handling industry and beyond. That puts us in a unique position.

We are fortunate enough to have a research and design team that works hand-in-hand with all of our departments. They work to meet the needs of all customers whether it's to do with a radio or motor control system for cranes and hoists, or a project for our elevator or conveyor team, we work in collaboration, sharing data.

OCH: What is your view on the future of the overhead cranes business?

DB: The future is exciting and bright in terms of evolving technology, acceptance of technology in learning different ways of doing things, and providing safer operations for overhead cranes, hoists and monorail systems.

With more diagnostic and analytic tools, than ever before, clients can better understand how their crane works and thanks to predictive analytics, when to fix or change something before it breaks down. Resolving an issue before it becomes a reality is key.

Company profile

Columbus McKinnon is a US-based company headquartered in Buffalo, NY, that was founded in 1875, with offices and manufacturing facilities around the world. The company’s Automation Division is based in Menomonee Falls, WI, with three buildings on one campus with approximately 340 employees. Columbus McKinnon employs over 3,000 people globally.

Daniel Beilfuss profile

Employment History

* 1989-1998: Pawling & Harnischfeger, Engineer

* 1998-2015: Magnetek

• 1998-2010: Manager, various departments including automation engineering, product engineering, product development, and business development

• 2010-2015: Director of sales

* 2015-Current: Columbus McKinnon

• 2015-2022: Director of sales, Magnetek material handling & wire rope hoists, North America

• 2022: General manager, Automation

Dan gives back to the local community though the Chamber of Greater Menomonee Falls & Sussex, where he serves on the board and helps develop future leaders in his community. As part of his work for this organisation, he serves as committee chairperson of the Leadership Moving Forward Committee, a programme that he himself graduated from in 2012. The prestigious programme selects high-potential leaders from the local area and develops them further with classes hosted by local businesses, including Columbus McKinnon. The programme aims to develop servant leadership and other leadership skills. In 2021, Dan was recognised for his achievements when he was honoured with the Chairperson of the Year Award. Dan is also a 30-year volunteer of the Milwaukee Irish Festival – one of the largest Irish ethnic festivals in the US. Over the 30 years, Dan has held various positions, including as a Jameson bartender. Dan is also an active member of his local church, where he volunteers throughout the year at various festivals and events.

Daniel's 5 tips for success

- You’ve got to develop trust. That is the most important thing between your company and clients, but also personally for yourself, and the people around you.

- Listen to others. Don’t do all the talking. Hear what others have to say and absorb what’s going on. Then ask questions based on what you’ve heard to make sure you understand what was being said and that you’re on the same page.

- Be open to new ways of thinking. That is something I’ve learned over the years. I struggled with it at the beginning but I’m getting better at it. I’m still evolving because we can all do better every day.

- Don’t be afraid to fail. We learn from our mistakes, and it helps us to improve our processes and make things better.

- Don’t be afraid to admit you don’t know something. We’ve all encountered people that think they know it all but it’s okay to say when you don’t understand something. That's why you have people around you to help you. That is so important and critical to this industry and in life in general, you don't have to know everything.