OCH: John, what drives you as an industry leader?

JP: Setting the goals of what you want to accomplish, building the plans to achieve that and then executing. I'm all about driving the execution and delivering results. However, in order to deliver the results, you really need an excellent team. Throughout my career, building great teams is something that I'm really proud of. The success of the execution comes from having the right team in place and then supporting them.

I’m also driven by a mindset of continuous improvement. Systematically, making progress, which includes the ability to change and adapt. Even when you know that the operations are performing well, the first question is ”How could we have made it better?” It is a systematic progression approach to continuous improvement as opposed to having everything perfectly detailed and organized at the onset.

OCH: What is your biggest business inspiration?

JP: To provide you a little background on MHI, it's a trade association representing the manufacturers and practitioners in the supply chain. Think of MHI as an umbrella organization and underneath that we have 18 industry product verticals. For example, CMAA, (The Crane Manufacturers Association of America); HMI, (The Hoist Manufacturer’s Institute), MMA (The Monorail Manufacturer’s Association) are all part of MHI.

We also have RMI (The Rack Manufacturer’s Institute); AS/RS (Automated Storage Retrieval Systems) and TRG (The Robotics Group), to name a few. These groups develop industry standards and deliver educational content to promote their technologies and the safe use of their products. They also provide market intelligence and statistics and opportunities to promote their companies as the leaders in the industry. You can visit mhi.org/industrygroups to see a complete list of the groups. Some of these groups date back to 1945 when several independent associations started and then they joined MHI.

Recently we have added new groups based on the technology development within the industry, for example, robotics. There was a time when there weren't many robotics solutions in the supply chain space but now that has changed with developments in machine learning, visioning, and gripping systems. We also added a group called SLAM, (Scan, Label, Apply and Manifest) which focuses on the last 100 feet in the warehouse operations which support ecommerce operations. Last year, we created AEC; the Advanced Energy Council, focusing on battery and energy technologies. We continue to expand the industry groups as the market and technologies expand.

In the industry verticals, we write 28 ANSI product standards (American National Standards Institute). These standards help to make the industry a better place to do business, focus on safe design and the safe use of products.

For me, the biggest business inspiration comes from the impact that the association has across the board on individual companies. We help members to grow their business, promote their technologies, and develop their employees. We provide market access for their business and provide a community for their employee development. The market access impact is delivered by connecting the manufacturers of the products with the people who use and implement them. This is done through producing the two largest North American supply chain trade fairs MODEX and ProMat, where the entire industry comes together. These shows bring the technologies to the people looking for these solutions on a grand scale.

I’m inspired by the communities that we build for technologies, marketing professionals, young professionals, and women in the supply chain. These communities build mutually beneficial network connections.

In addition, we provide knowledge on the latest trends, technology, and education to help people advance in the marketplace. Overall, I’m inspired by the impact that the association has on the supply chain industry.

OCH: What is your business philosophy?

JP: It starts with building a strong team, that allows you to execute and deliver. The key is having a great team in place and then providing the direction, guidance, and support for them. If I look back at my career, everything has been built around having a really strong team and knowing they can execute on whatever types of projects we would get involved in. Another key is being able to adapt to change. Our markets have changed considerably from a technology perspective and overall market dynamics.

My philosophy is to build a great team, adapt, adjust, improve, and deliver. That has served me well throughout the years.

OCH: Why and how did you enter this business?

JP: I am originally from Pittsburgh, Pennsylvania, and I went to The Ohio State University and earned a mechanical engineering degree and followed up with an MBA. My first role was to write software programs that can automatically configure overhead crane systems. In the mid- 1980s, most drawings and designs were done by hand with a pencil and paper on a drafting table. So that was a unique opportunity to be able to develop those type of software systems that would automatically design, configure, price, and draw the enclosed track crane systems. At that time, that system was pretty advanced.

From there, I moved into product management, outside sales, operations, and division management roles. I performed many different jobs within the company both inside and out and that ultimately led to becoming President of Demag Cranes, North America, a position that I held for 15 years. It was a step progression career of learning by doing.

During that time, since Demag was a member of CMAA, HMI and MMA, I became involved with MHI. I volunteered for many different groups and was chair of CMAA, HMI and MMA. I then joined the MHI Roundtable Advisory Committee and was elected to the board, then became chair of the MHI board. When the previous CEO, George Prest, announced his plans to retire after 10 years, it was a great transition for me to move into that role. I always believed that by being a part of the association, you get to see the entire view of the industry and it was an honor to join the association.

OCH: Tell us about your success stories?

JP: In the early days, during my crane and hoist career, the highlights came from executing several specific large, complex overhead crane projects which included heavy capacity, long spans, integrated technologydriven cranes. Our success came from taking calculated risks. Saying “Yes we can” and going beyond our capabilities by taking on these challenging projects. We knew that we had the skillset and the backing of our teams, and we knew we could deliver. Then once the project was complete, that became our new baseline of capabilities and that set the stage for what we could do to take the business to the next level.

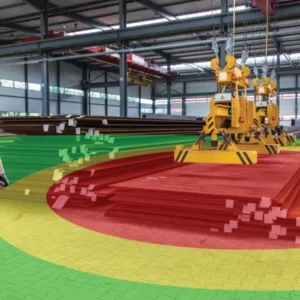

Our largest crane had a 450M ton capacity. We had several very long span cranes, automated cranes, and cranes installed in many tough environments. When we took on those projects, we weren't always sure in the beginning. But we knew we were offering high performance products so that naturally led us to the high-performance applications such as; automotive, aerospace, shipbuilding, foundries, etc. These tough applications continued to stretch our capabilities. As we were successful, it led to new opportunities and even more challenging projects.

Looking from an MHI perspective, the success came from navigating the disruptions from COVID. All companies were faced with those challenges, and I happened to start my role as MHI CEO right in the middle of the pandemic. As an association, the organization is centered around bringing people together. The challenge for our team was how do we continue to help our members to navigate the supply chain challenges while not being able to bring the industry together. Like everyone else, we were learning as we went, but we were able to continue to help our members and engage with them through a very difficult time. Due to our ability to adjust and adapt, we have come out of that time even stronger. Now, all of our events have reached record size and attendance.

OCH: Tell us about your failures and how you overcame any challenges.

JP: Looking back at my crane career, I'm sure all crane manufacturers will appreciate, that when you build custom projects, not everything goes perfectly. However, one of our core philosophies was to provide extraordinary customer service. Make sure that our customer was completely satisfied and find ways to “WOW” them. If there were challenges, we always made it right and that’s how we built long term customer relationships. Our customers knew they could count on us. Not only did they know that they purchased high performance products, but they knew that we would stand by our products. We would execute a project, and then continue to offer our local service to back it up.

OCH: What do you like about this business?

JP: Cranes and hoists are used pretty much everywhere in every industry. What I enjoy most about my career is seeing how everything is manufactured in every industry and how overhead lifting technologies made that possible. I had the opportunity to go into so many different facilities around the world and see how things were made.

One day you could be in an automotive facility and in another watching how aeroplanes or windmills are made. I even toured a cookie facility and saw how they used the hoists in their operations to make cookies. Now, in my role with MHI, I have the opportunity to see the entire industry and how all of the technologies are implemented.

OCH: What do you dislike about this business?

JP: I’ve had such a great career. I have learned so much. There is nothing that I disliked. Even the travelling was great. At Demag our headquarters was in Germany. I would go there on a regular basis and had the opportunity to travel throughout Europe and meet people from all over the world. It was a great experience.

OCH: What makes MHI unique?

JP: MHI is unique, due to the collaboration and the building of a community. We bring together companies in 18 industry verticals, many of whom are competitors. But they all come together to make the industry a better place. That, in itself, is unique. They work to write standards and publish safety information for the betterment of the industry.

There are not many organizations that represent so many different industry verticals and there are so many crossover points. For example, when someone is building a new facility they don't just want one product, they need many different technologies in that facility and all those technologies fall under the MHI umbrella. That is how the community provides full access to these solutions.

OCH: What is your view on the future of the overhead cranes business?

JP: Cranes and hoists have been around for a long time and even though it sounds like a cliche, as long as there's gravity, cranes and hoists will exist. But the industry has developed from the mechanical components of gears, motors, sheaves, ropes and chains to systems that combine electrical technologies to make advanced machinery.

When I started my career, motion control was done with two speeds or DC resistor banks. Inverters were not common. Now, controlling speed, is not only done with inverters, but a combination of computers, sensors, and radios. Beyond that, the data management for preventive maintenance is more prevalent. The products have moved on from a combination of mechanical devices to full blown integrated advanced machines.

All these technologies continue to advance and there are exciting times ahead. The products have really come a long way from what I've seen throughout my career and the outlook is positive.

Cranes and Hoists will always be needed. Now the focus in on making them as high performing, efficient and as safe as possible.