MMA members promote the importance of patented and enclosed track underhung cranes and monorail systems with programmes and policies reviewed and adopted by the membership, with representation from each member company. The body is represented on a number of standards developing committees and actively supports the development and certification of safety standards by ANSI (the American National Standards Institute).

OCH: What drives you as an industry leader?

LB: I enjoy taking on a challenge. My position allows me to see the full scope of the project from beginning to the end result and work closely with the customer in the process. It’s interesting to look at a wide variety of applications and the challenges that they present. I enjoy coming up with unique solutions that meets their needs – that’s what drives me.

I’ve been in manufacturing for 40 years, and the crane industry for the last eight, which is the same amount of time I’ve been with MHI.

OCH: What is your biggest business inspiration?

LB: I am a problem solver at heart and always try to improve the efficiency of applications for my customers. It is very rewarding when I see that my ideas have had a positive impact on cost savings, productivity and workplace safety. I grew up wanting to be an engineer and have built my career in that field. I would always rather be physically involved while working on a project instead of sitting at a desk. So, dealing with the crane and vacuum industry with their different applications brings me a lot of satisfaction.

OCH: What is your business philosophy?

LB: I try to put myself in the position of the customer and ask myself if I would be satisfied with this product? My goal is always to try to provide something that I myself would be happy using. I am pretty particular, so if I’m happy, then usually the customer is also happy.

OCH: Why and how did you enter this business?

LB: I’m a mechanical engineer by trade and a licensed professional engineer.

I was born about 60 miles south of Pittsburgh, PA, in the coal mining and steel industry area and graduated high school there. I moved to Atlanta to attend the Georgia Institute of Technology where I gained a bachelor’s degree in mechanical engineering. From there, I went to Charleston, SC, to work for the Robert Bosch Corporation and then came to Raleigh, NC, to start a manufacturing facility for Schunk.

Like I said, I’ve been in manufacturing for 40 years, dealing with everything from high production manufacturing of automotive parts at Bosch, down to lower-volume production of hydraulic tool holders at Schunk. I’ve primarily worked for German companies where things were typically designed and produced in Germany first, before being manufactured in the US.

Once it was decided that the product would be produced in the US, my job was to determine what processes and equipment we would duplicate and what we would do differently. I learned all about the details of manufacturing the product and the technology necessary to transfer it to the US. Finally, we would install equipment, conduct training and get production up and running. That is what I did for Robert Bosch on a very large scale, then on a smaller scale at Schunk.

I eventually was a partner in a business doing custom automation and designing and building custom equipment. Many of these items were made for Schmalz.

Eleven years later, I decided to join Schmalz. I was already familiar with their products and had been designing and building a lot of their custom equipment. It was at that point when Dr. Schmalz wanted to transfer the crane technology from Germany, which started ten years earlier, to the US. He knew my background and my experience with transferring technology and starting manufacturing. That is how I got into the crane industry. A year later we were producing aluminium cranes in the US. I am very proud of that accomplishment.

OCH: Tell us about your success stories

LB: The details of a lot of our projects are protected by non-disclosure agreements, but we do custom projects for a variety of companies in diverse market sectors. We work with Amazon, Walmart and Chewy, providing lifters to help them move and package product in their distribution centres.

We provide workstation cranes and lifting equipment for Tesla in their automotive assembly facilities in California and in Texas.

We have also produced a lifter for Vestas that is over 200ft long to remove components of wind turbine blades out of a mould.

Like I said before, I consider one of my biggest success stories to be the successful start-up of crane manufacturing in the US to produce the Schmalz aluminium cranes.

In addition to my work at Schmalz, I am also proud of what we have accomplished so far during my tenure as president of MMA.

MMA is an association of friendly competitors. Our members comprise approximately 70-80% of the current market share of US workstation cranes. We all have similar products, but each company has their own unique features which separates them.

We have worked on revising the ANSI standards for workstation cranes. These standards come up for review every few years. This time we decided to do a complete revision and update the standards – one for enclosed track and one for patented track. We are now at the point where the standards have been revised and sent out to a canvassing committee for review so we can submit them to ANSI for publication. It’s been a long journey and again, MMA is a volunteer organisation. We all have full-time jobs, but we meet monthly online and twice a year in person, in the spring and fall. The final version is expected to be published by ANSI by the end of next year.

OCH: Tell us about your failures and how you overcame any challenges

LB: I try to learn from my failures and not let them discourage me. I would have to say my biggest failure was not being able to sustain my business partnership. I was building custom equipment for 11 years and there are a lot of challenges that come with that. Not only are you designing and building, but you’re also trying to be the salesman and keep your pipeline filled with projects. Eventually, as it grows it can be a bit overwhelming. I decided to step back, but stay in the same industry.

A lot of the custom products we were making were for Schmalz. I knew the people and the president very well. So, when I decided I needed to make a change he was the first one to reach out to me and invited me to join the company.

Any time you’re working on projects, there are always times when things don’t exactly go as planned and you have to step back, reevaluate it, make changes and come up with a solution that works. There have been failures along the way, but none of them have been catastrophic.

OCH: What do you like about this business?

LB: I enjoy dealing with other people in the industry. Not only engineers, but marketing people from different companies – some are competitors, some are not. For example, we produce our own cranes here, but we also partner with Gorbel.

For years, we sold Gorbel cranes before deciding to make our own, but we still work with Gorbel on a regular basis.

In MMA also, it’s been great getting to know people who lead these other industries and companies. When you have a similar interest, there’s a natural synergy in the group. It’s funny because when people ask me “what do you do for a living”, it’s hard to explain it to somebody who’s not in the industry. So, it always helps to be in a group that understands exactly what you do.

I enjoy working on custom projects with our outside sales guys. I also like working with our younger application engineers, to help them with custom projects they’re working on to try to mentor them and advance their knowledge base, passing on what I’ve learned over the last 40 years to someone else who can learn from my experiences and mistakes.

OCH: What do you dislike about this business?

LB: Overall I enjoy this industry, but the crane and lifting products that we produce can be mis-applied and misused. Despite repeated training and warnings, some end users decide not to follow our recommendations, resulting in a situation where operators are put at physical risk. First and foremost, our focus is on making sure we provide a safe product. For me, the old adage of ‘the customer is always right’ doesn’t apply to safety. Sometimes I have to make that abundantly clear to our customers, which does not make me the most popular guy in the room. I accept that as the responsibility that I must carry as the engineer.

OCH: What makes your company unique?

LB: Schmalz is a German-based company, which has been in business for over 100 years, and they’re in 31 countries now. It is a privately held company, and the US is its largest subsidiary. The main focus is on vacuum lifting, but the business is divided into two sections: the automation side provides all the components and end-of-arm tooling for robots, the material handling side provides lift assist devices.

A company that is not yet ready for automation with robots but still needs lifting equipment can benefit from something that is on the manual handling side of our business. With vacuum tube lifters for porous products and vacumaster systems for non-porous products, we can lift almost anything, from loading wood or metal onto CNC machines, to stacking cardboard boxes, to handling glass for window and doors. These types of lift-assist devices, centred around ergonomics, reduce injuries, making things easier for the operator.

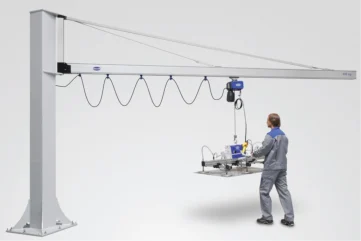

About 20 years ago Schmalz realised that the crane being used for in conjunction with these lift-assist devices had a huge impact on their ergonomics. If the moving portion of the crane weighs more than the product being moved, the crane takes away some of the ergonomic advantage of the lifter. At that point, Schmalz decided to develop its own line of aluminium cranes that are matched to the capacity of our lifters to make a complete ergonomic lifting system.

That’s why we are not a typical crane manufacturing company. Rarely do we sell cranes that do not have one of our lifters hanging underneath it. Our cranes were developed to be part of an ergonomic lifting system.

OCH: What is your view on the future of the overhead cranes business?

LB: Cranes will always be an integral piece of equipment in manufacturing and material handling. Primarily, when people think of cranes, they think of large cranes capable of handling many tons. From our perspective, companies also need cranes to be able to move lighter loads as well. This lower weight capacity sector promises to provide growth in our industry.

With the ever-tightening workforce it’s harder to find people to do the heavy manual labour that we’ve seen in years past. Companies are providing ergonomic lift assist for their employees, not only to reduce injuries, but to expand the potential employee pool.

Even in my role at MMA, it’s not something I sought out, but when you’re in a small group, everybody needs to do their part. Leading this group gives me great satisfaction in knowing that I am helping to push the workstation crane industry forward.

Company profile

Schmalz is the global market leader in vacuum automation and ergonomic handling solutions. Schmalz products are used worldwide in applications in the food/pharma, logistics, glass, metal, automotive, packaging, and wood industry sectors.

The wide range of products in the Vacuum Automation unit includes individual components such as suction cups and vacuum generators, as well as complete gripping systems and clamping solutions for holding workpieces. The Handling Systems unit offers innovative handling solutions with vacuum lifters and crane systems for industrial applications.

With comprehensive consulting, a focus on innovation and first-class quality, Schmalz offers its customers long-lasting benefits. Schmalz’s intelligent solutions make production and logistics processes more flexible and efficient, while also preparing them for the increasing trend toward digitalisation.

With its own locations and its sales partners, Schmalz is represented in more than 80 countries and in all important markets. The family-owned company founded in 1910 has over 1,800 employees at its headquarters in Glatten (in the Black Forest region of Germany) and its 31 international subsidiaries.

Schmalz’s US headquarters in Raleigh, NC, has been in operation since 1993 and employs over 125 people.