Overhead crane firm CRS has designed and manufactured a custom-made solution to operate deep underground at a potash mine in Saskatchewan, Western Canada.

Attached to an elevator, the crane is used for the removal of the steel structures that help facilitate the mining of potash – such as beams – from the bottom of the shaft onto the elevator for transport 1km up the mine shaft. When undergrounded it reaches out beyond the elevator to access the load, before tucking away within the elevator structure to avoid interfering with the shaft on the way up.

The process of producing the crane began when the client – which had worked with CRS on previous, more standard, projects – approached the Canada based overhead crane company with a concept it wasn’t entirely sure was workable.

“They came to us and said, ‘Hey, we have a concept for a lifting system and want to know if it is feasible,”says Chris Roots, vice president of sales, at CRS.

“We did some preliminary calculations and concept sketches and reviewed the requirements with component suppliers and our own engineering team and confirmed with them that ‘yeah – we can make this work’. We then just had to prove it all with the actual designs as opposed to the hand sketches. [But] based on our initial planning we were confident we were going to make everything work and accepted the contract.”

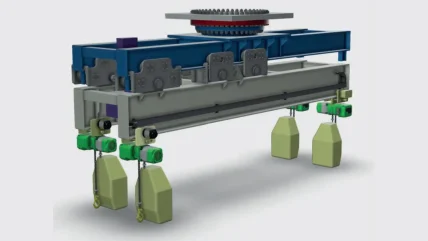

CRS faced several challenges that had to be overcome: the client wanted a crane that could handle different lifting scenarios using up to four hoists, which required the structural design to include distinct categorisation of loads; plus CRS had to maintain high safety requirements while keeping the unit weight within elevator load limitations, and ensure control of the system and its programming due to the high number of inputs and outputs.

Then there was the issue of the crane working in an environment with limited space.

“They had very limited space to fit the crane system into – it couldn't be extended. So it was either everything was going to fit or it just wasn't going to work,” explains Roots.

Using SolidWorks software, the design went through several revisions.

“We work through everything with detailed 3D modelling,” says Roots. “We went through almost nine months of design – back and forth – and modelling to address all of the clearance issues and operational requirements before we finalised on the actual design.” The 17.6-ton crane solution uses dual extending run-out monorail beams that are attached to each other, with each beam having two 5.0-ton Kito ER2 electric-chain hoists with 150ft lift. Electric chain hoists were selected to ensure ‘true vertical lift’, and also due to their smaller physical size, compared to electric wire rope style hoists. Typical flat cable festoon systems were replaced with Igus energy track-style power supply systems to also minimise the overall crane footprint. Even though the four hoists provide 20-ton lifting capacity in total, the load cell summation will limit the total capacity to 17.6 tons, the maximum considered lifting capacity, or 4.4 tons each.

The company integrated a full logic and control system so that the hoists can function in all configuations, including independently, up to a fourhoist synchronised unit.

CRS coordinated with the client on the loading requirements at full extension and putting limiting controls and load summations in place to prevent overloading of the structure. Meanwhile, using finite element analysis (FEA) to find areas of lower stress in the structure enabled the overall weight of the system to be significantly lowered to stay within weight restrictions.

“Intensive technical development was required to ensure a safe, reliable and efficient control system,” CRS adds.

The client was pleased with finished design. “With their extensive experience and design expertise, especially in the mining industry, we knew it was the right choice to partner with CRS in custom designing a crane that would meet our unique, deep-underground needs,” it says.

Dedicated test stands were designed and built at CRS to ensure operation and functionality of the units could be finalised and the units could be load tested in our facility prior to shipping to site. Further load testing of the unit at the site too was carried out prior to installation – due to the challenge of having the test weights at the bottom of the shaft, the tests had to be done on the surface, on an above-surface test stand.

The job, meanwhile, was unlike any other CRS has attempted before, although it hasn’t been its most difficult challenge to date.

“It is a big part of what we do – we build a lot of standard cranes, but we also have the capabilities to design and build very customised solutions for our clients” says Roots. “We're always solving problems one way or another. It’s something that we're good at and what we do a lot of.”

Work on a second, identical unit for the client to use at the same site, but a different mine shaft, is already well underway.