Key information

Where: McCormick Place, Chicago, US

When: 20-23 March 2023

More details and register? www.promatshow.com

Seminars and keynotes

A flavour of the seminars on offer…

- Cutting through the noise: How to look beyond technology and meet business objectives

- Minimise supply chain disruptions with innovative technologies

- Extending the life of your existing facility

- How safety can help solve your hiring and retention problems

- To automate or not to automate in 2023 and beyond

- Strategic planning for uncertain times

…and the four keynotes you can attend

- Women in Leadership Panel – Moderated by Michelle Dilley, CEO of Awesome

- A Conversation with José Andrés – Chef and founder of World Central Kitchen

- ? Preview of MHI 2023 Annual Industry Report – John Paxton, CEO, MHI and Deloitte Consulting LLP

- ? A Conversation with Ron Howard – Director, cultural icon and actor

This year’s exhibition takes place in Chicago on 20-23 March and gives supply chain professionals the opportunity to witness demos of cutting-edge tech and solutions, as well as meet up with their peers.

Among the more than 1,000 manufacturing, distribution and supply chain equipment solution providers that will be exhibiting – representing all segments of the material handling, logistics and transportation industries – will be overhead crane company Handling Systems International (HSI). The company’s director of business development, Bret Lussow, says: “It’s good to be back at Chicago after four years (because 2021 was virtual). We enjoy this show as it is in our home town.”

He went on to say that HSI will target its expanding dealer network at the event, and that he looks forward to seeing many familiar faces: “We will have many dealers visit our facility that week as we are only 12 miles from the McCormick convention centre, and we are planning on hosting a dealer event one evening.

“We will be showcasing our fast-growing NikoRail enclosed track product as well as some specialty items that will be a surprise to our customers.”

Reacting to the total number of exhibitors at the show surpassing 1,000, Steve Napieralski, president of Oz Lifting, says: “Having that many exhibitors should draw a lot of attendees, and Chicago being a central location should help as well. The cons, however, are you can get lost in the maze of exhibitors. We plan on getting the word out that we will be exhibiting and will be inviting a lot of distributors.”

Among the products on show is Oz Lifting’s Aluma-Lite “ultra-portable” davit crane. It is available in maximum 500lb and 1,000lb capacities, each available with three bases: pedestal, socket (flushmount) or wall-mount. The Aluma-Lite 500 weighs 24lb, while the Aluma-Lite 1,000 weighs 47lb. Both fold flat for storage or transportation, are made of aerospace/military-grade aluminium, and are available with a manual winch (including drill drive adapter), and AC or DC electric winches. No tools are needed for assembly/disassembly.

The Tele-Pro davit crane will also be on show, as will several stainless steel products, designed for use in corrosive environments, including hoists, beam clamps, trolleys and a manual winch with a drill-adaptor feature. Spark-resistant hoists and trolleys will be of interest to exhibitors too.

“As with all products in our range, the new davit cranes fill voids in the material handling marketplace,” says Napieralski. “As such, we expect the [Aluma-Lite and Longreach] davits to be especially popular, but our composite products always seem to attract attention.”

Another familiar name at ProMat is Konecranes. It will be showcasing its Automated High-Bay Container Storage system, a solution designed to “revolutionise” container-based material handling, increasing efficiency and safety in the process. The company says it would be of interest to attendees who need to manage/handle significant amounts of containers, or those faced with inefficient processes or issues surrounding scarcity of land in green or brownfield developments.

The system utilises a purpose-built high-bay warehouse, allowing, says Konecranes, for a higher storage density and faster retrieval times compared to traditional manual methods. The solution offers automation, container stacking (up to 12 loaded/14 empty containers) and a retrieval/access time of two to three minutes.

Konecranes says the system “eliminates truck yard congestion, thus improving safety and ensuring fast truck turnaround times, significantly reducing trucking costs and pollution in the area”.

“We are excited to be introducing the Automated High-Bay Container Storage at ProMat,” says Tero Vallas, business development manager at Konecranes. “We believe this solution will have a significant impact on container-based material handling, and we look forward to demonstrating its capabilities to the industry.”

Experts will be available at the Konecranes stand to answer any questions and discuss how the technology can benefit their operations.

HBC-Radiomatic, meanwhile, will be showcasing the latest innovations in wireless control technology, highlighted by the release of the Spectrum series of controls that are equipped with 5.0in colour displays, allowing for more operator feedback and control possibilities. HBC will also be displaying new options and features such as Radiomatic touch-toactivate, function-select joysticks and computer tablet mounts that allow for more direct human-to-machine interface options for crane and heavy equipment operators.

MATERIAL HANDLING

Moving away from the overhead cranes community, the raft of material handling companies present at the show will include Kardex, a manufacturer of automated storage and retrieval systems (ASRS). It will provide ProMat 2023 visitors an immersive digital experience. Showcasing vertical lift modules, vertical carousel modules and vertical buffer modules, ProMat visitors will see automated solutions come to life through augmented reality.

The ASRS technologies operate on the goods-to-person principle, delivering stored items to the operator at an ergonomic access point with the push of a button. Kardex says high-density automation can reduce a firm’s storage footprint by up to 85%, increase pick accuracy and reduce labour requirements for more efficient warehouse operations.

Kardex says its experts will be on-hand to provide visitors with the best solution for their business, but for anyone who can’t make it to ProMat’s Booth 4325, Kardex’s virtual exhibition can be found here: kardex.com/en/company/virtual-exhibition.

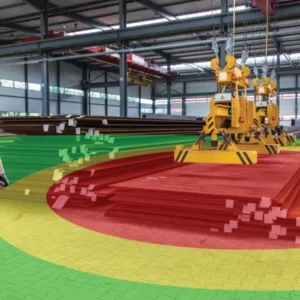

Meanwhile, active safety provider Advanced Microwave Engineering (AME) says that a new era in safety technology will be revealed at ProMat 2023.

Its Amesphere is a safety-as-a-service cloud-based platform that uses data and real-time information to avoid collisions, allow vehicles and people to work safely together, and provide peace of mind for operators and management.

AME says it is easy to install and uses anti-collision technology that is precise to the centimetre. It also adaptable to the needs of all workplace environments

“We are very excited about Atmosphere,” says Claudio Salvador, president and CEO at AME. “It is the ultimate innovation to enhance protection and provide the perfect balance between safety and efficiency in the workplace. We are inviting everyone who is involved in site management to come and see how it works and how it will protect personnel, reduce operating costs, and add value to the business.”

Salvador concludes: “This is real gamechanging technology in how companies approach safety and takes us closer to making accidents a thing of the past. What a goal that would be!”

AME experts will be on hand at Booth N6422 to answer your questions.

Material handling equipment provider Blue Giant Equipment Corporation will also be at the show. Last autumn, it acquired controlling interest of ergonomic lift assist solutions company Cormac Industrial.

Located in Mexico, Cormac Industrial is a manufacturer and provider of industrial ergonomic lift assist equipment, including air balancers, jib cranes, overhead enclosed monorail systems, pneumatic lift tables, and lift assist systems. It has been providing engineered lift assist solutions for more than 30 years, for companies such as power technology firm Cummins and automotive businesses Volkswagen, Nissan and Stellantis.

“As we expand our focus on providing ergonomic lift solutions, Cormac’s expertise and success in work cell and assembly line engineered ergonomic lift systems aligns perfectly with Blue Giant’s goals. We are excited to have Cormac as part of the Blue Giant family,” says Steve Barbosa, president at Blue Giant.

James Patton, president at Cormac Industrial, adds: “We are excited about the energy and momentum we have with Blue Giant and the opportunities for growth. Together, we look forward to innovating and expanding our lift assist solutions and selling products globally that improve safety and productivity.”

Together with Cormac Industrial, Blue Giant plans to broaden its ergonomic lift solutions product portfolio within the US and Canadian markets through its distribution network. To find out more, head to Booth S447.

NO SUBSTITUTE

“There is no substitute for ProMat, where you can see all of the products in action,” says John Paxton, the CEO of MHI, the international trade association that represents the material handling, logistics and supply chain industry and which is behind the event. “You will find the solutions to your specific operational challenges – from the exhibits, during the educational sessions and by speaking with the leading innovative material handling and supply chain suppliers.

“We are excited to provide this market access and knowledge opportunity for our entire community.”

“Seeing the large array of solutions, meeting with leading suppliers and connecting with peers will allow attendees the opportunity to discover products, services and technologies that will be essential for their success in the future,” adds Daniel McKinnon, EVP of exhibitions, MHI.

As well as the exhibitors, the ProMat 2023 Conference will include four thought-provoking keynotes and more than 150 of the educational seminars highlighted by Paxton, covering leading trends, best practices and state-of-theart equipment and technology solutions that can make manufacturing and the entire supply chain work more resiliently, efficiently and profitably.

“The educational sessions are good for the industry. Any time you can offer learning, those attending are there for a reason. They will gain a new concept or learn something new that helps their business,” says Oz Lifting’s Napieralski.

There will also be an MHI Industry Night of music, food and drinks, with entertainment by the comedian Nate Bargatze, a Women in the Supply Chain Industry Forum, an MHI Young Professionals Network Reception, and a ProMat Student Day.

The Raymond Corporation

Last autumn, the Raymond Corporation, a Toyota Industries Company, and a provider of material handling products and intralogistics solutions, introduced a couple of new products. First up is its latest addition to the iWarehouse Fleet and Warehouse Optimization System portfolio: the iWarehouse FieldSense (iW.FieldSense) proximity notification system (pictured, right).

It uses magnetic field generator (MFG) technology to see through and around most objects – including racking and corners – to alert pedestrians and lift truck operators when they come within a predefined distance of each other.

“It’s designed so warehouse managers can customise it to best fit their operators, applications and facility layouts without significant infrastructure changes,” says Steve Gorr, application manager for iWarehouse Solutions at the Raymond Corporation.

The vehicle-mounted MFG creates an adjustable field around each piece of mobile equipment. If a pedestrian-worn pedestrian notification device (PND) detects a field, the PND sends a notification to the MFG, which then notifies the vehicle-mounted notification device for the vehicle operator to see.

Using this field, iW.FieldSense can provide three levels of awareness: truck-to-truck, truck-to-pedestrian, and truck-to-facility.

The other product launched was the High Capacity Orderpicker (pictured, right). Designed to facilitate order picking a full rack higher than other models, the lift truck is said to deliver market-leading capacity at all heights and reduces annual cost per pallet stored by 19% compared with competitors. The orderpicker is also said to feature an industry-leading elevated height of 456in, which allows for increased rack storage access to 11% more pick slots. The increased elevated height enables operators to optimise storage capacity for more usable space and improved Sku count without increasing a facility’s overall footprint.

Other features include lithium-ion battery technology; In-Aisle Detection System, which notifies operators travelling in the tractor-first direction when the system detects objects in the lift truck’s path; and Zoning and Positioning technology, which “ensures more reliable and repeatable lift truck operation by controlling many order-picking functions”.

For more information on both products, head to Booth S1703.

Forklift news

UgoWork, a Canadian energy solutions provider, will be at ProMat too. It has revealed that its lithium-ion (li-on) battery line-up for industrial trucks can now be used to power lift vehicles from a major OEM it wouldn’t name by the time Hoist went to press. This announcement comes on the heels of UgoWork’s battery solutions being certified by another, globally renowned OEM.

Last autumn, the company announced the arrival of Tim Ballard as director of sales. He has worked in several management positions at ProLift Industrial Equipment, an official full-service and material handling dealership for Toyota.

“I was very impressed with UgoWork’s vision and the performance of both its lithium-ion batteries and energy-as-a-service (EaaS) model,” says Ballard. “No other manufacturer offers these types of solutions on the market – a solution that truly addresses today’s material handling challenges.”

Ballard continues: “I want the business to have the very best sales team in the industry so that we can educate and serve material handling teams across North America about the benefits of lithium-ion batteries and EaaS as compared to other legacy technologies. UgoWork’s future looks very bright indeed.”

Ballard will be at the event. You can say ‘hi’ to him here: Booth N6760.

If you’re interested in more lithium-iron battery tech, then take a stroll to Booth S1568. There, Noblelift will be able to talk you through its FE4P50Q, FE4P60Q and FE4P70Q four-wheel forklifts. The vehicles use lithium-iron phosphate batteries (a li-on variation), which have ten-year or 20,000 hours warranty and can be fully charged in two to three hours. The company says lithium-ion batteries have a 3x longer lifespan than lead acid batteries, can be charged and discharged more times before they need to be replaced, and are more environmentally friendly and recyclable. To see a total cost of ownership comparison between lithium-ion and lead acid, visit https://bit.ly/3B9NZQe.