The State of Illinois, the City of Chicago, Google and the Prime Group/Capri has agreed to redevelop the James R. Thompson Center in Chicago, to revitalize the Loop and LaSalle Street, bringing in 5,000 new jobs downtown.

The investment is seen as a major boost to the city, which is grappling with high vacancy in office buildings as employers let workers adopt remote and hybrid work schedules. That has exacerbated a trend of companies moving out of older Loop buildings for new towers along the Chicago River and in the Fulton Market district, a movement that began before Covid.

The news coincides with plans for the Chicago Bears to build a fixed-roof stadium along Chicago's lakefront. The Burnham Park Project includes a publicly-owned multipurpose replacement stadium south of Soldier Field that's part of a singular year-round hub centered on park-based culture and recreation.

"This is an incredibly special day for the Chicago Bears," said Bears President and CEO Kevin Warren. "Today is about progress, and one of the things I am most excited about today is the fact that this shows in this city we have the intellectual capabilities, we have the heart, we have the passion, we have the foresight, we have the wisdom, we have the vision to do big things."

The proposal boasts year-round use for recreational and community events and an increase in open and green space, including 14 acres of athletic fields and recreational park space for use by public and youth sports programs.

Electric vehicle manufacturer Rivan also announced it will move R2 production from its planned Georgia plant to, Illinois, to speed up deliveries of its mass-market SUV customers.

The California-based car maker said Illinois will provide $827 million in subsidies to support expansion of its plant in Normal, Illinois to build the R2, two-row vehicle.

A Rivian spokesman said the Illinois subsidies will help the company bring the R2 model to market faster, “allowing us to transition and quickly resume work in Georgia when the time is right.”

Finally, following a generation of funding cuts in the last five years, Illinois has enacted a series of reforms to keep graduates in the state.

Increased funding through AIM High, MAP and iGrow grants has been a lifeline to low-income students, particularly students of color, rural students and working adults.

But more investment is needed. Colleges nationwide face an enrolment struggle after decades of rising tuition and declining birth rates. In Illinois, public university enrollment has declined 17% since 2014. Yet college degrees are more essential for securing high-paying jobs than ever before.

Illinois needs to produce and retain more college graduates to sustain local communities and develop a pipeline of skilled workers ready to compete in the global economy.

To find out more about what’s happening in this industrial manufacturing state, OCH chats to some local entrepreneurs.

“The Illinois market is good. It is the heart of the Midwest, centrally located to major manufacturing in the region and has great access to raw materials particularly steel, good availability of manufacturing talent and is centrally located to service and transport to the rest of the United States,” says Bret Lussow, director, Business Development, Handling Systems International (HSI) McCook, IL.

“It is known for hardworking, highly educated people with good values and companies offering good wages. Those who live and work in Illinois are often dedicated and loyal.

“There are some local issues that can be challenging at times. Cook County (Chicago) has higher taxes and cost of living than the rest of the state resulting in higher wages for our workers. There can also be logistical issues getting through and around the city with larger loads. The state does a good job of offering property and tax incentives to lure and keep buildings occupied and business in Illinois.”

In recruiting the younger generation into the industry Lussow says it has 'a very large pool of applicants'.

“There are nearly nine million residents in the greater Chicago area so this is not as big of an issue as the rest of the country. Applicants seem willing to travel greater distances than in the past knowing they can have a flexible work schedule or work from home on occasion,” he said.

“Currently, HSI works exclusively through our dealer network; our business is very diverse and not regional. We continue to expand our operations and recently opened our second facility in Chicago.

"Our NIKORail product continues to grow and we are expanding into non-traditional markets such as paint booths and conveyor systems. HSI recently launched a new and improved trackless gantry crane possible of inversing and indexing in confined spaces as well as continued focus on bridge cranes recently designing and manufacturing HSI’s first box girders.”

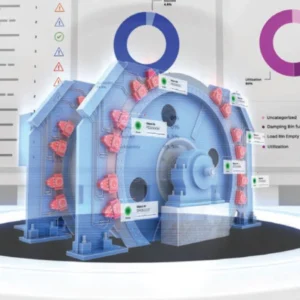

According to Ryan D Marks, president, Uesco Industries, the overhead crane market in Illinois remains robust, driven by the state's strong industrial and manufacturing sectors, particularly in the Chicago area.

“Being based in Illinois offers significant advantages due to its strategic location, welldeveloped infrastructure, and a rich industrial heritage that supports a diverse range of industries from automotive to aerospace. However, the market faces several challenges, including economic uncertainties that can impact capital investments, stringent regulatory requirements for safety and operational standards, and ongoing supply chain disruptions that affect the availability and cost of materials,” he said.

“Additionally, recruiting the younger generation into the industry is an ongoing issue. Many young professionals are gravitating towards tech-focused careers, leaving a gap in skilled trades. To overcome this, the industry must invest in outreach programs, partnerships with technical schools, and apprenticeships that highlight the rewarding and technologically advanced nature of modern crane work.

"At Uesco Cranes, we are continuously innovating to meet market demands, incorporating advanced technologies like IoT and automation into our products. Currently, we are engaged in several key projects across Illinois, including modernizing crane systems for large manufacturing plants and expanding our service offerings to ensure optimal performance and safety for our clients. Our focus remains on enhancing efficiency, safety, and reliability in all our operations.”