ECMA announced it was rebranding to become ACE last year because it wanted to have an industry group within MHI that would serve the automation, controls and electrification needs across the entire material handling ecosystem – everything from the shaft of the motor all the way to the factory network or cloud.

Dan Barrera, vice chair, ACE and sales product manager, Bosch Rexroth, said at the time, the rebrand allows members to have a new value proposition regarding machine safety, connectivity, data collection and security with encryption, to create high-performance architectures or solutions.“We have a vision of creating a map of all the groups and how they link to each other,” he said. “ACE can be at the center within MHI of all of the different things that require automation.”

Here to tell us more about the evolution of the group are ACE members, chair Jason Looman, Miguel Tellez, Tele Radio America; Brian Cook, Conductix-Wampfler; and Brett Schneider, HBC-Radiomatic.

OCH: Jason, tell us what was the reason behind the rebrand?

JL: First, we rebranded ECMA to ACE because as an historic association of predominantly crane component suppliers, over the last 15 years the entire material handling industry has been evolving to integrate all equipment in factories and warehouse into one total environment. The ultimate aim for the end users is to have an integrated infrastructure whereby each component of the factory floor will be able to adjust based on feedback from the prior equipment and use above stream.

For the last couple of years, given AI and an explosion of new automated technologies, we saw as a group the need to bring together all members of this world of sensors, controls, communication, motors, software, electronics and electrification to discuss how to make these dreams a reality. However, as an association that is enabled to write specs, to also make sure we promote the safe and reliable control of the new systems.

With today’s technology, anyone can use a multitude of technologies to achieve their goals of an autonomous world of equipment. However, we want to make sure everyone is always keeping safety at the forefront of their considerations. For example, some equipment suppliers have built controls based on Bluetooth and WiFi as they are easy to use and readily available communication technologies. However, without proper protocols these may not meet the required safety restrictions that ensure user safety.

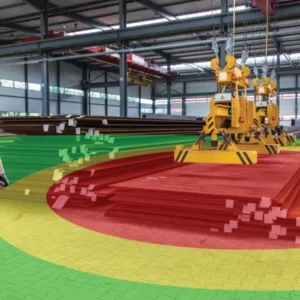

For the overhead crane industry, we are seeing requests for their integration into the entire plant controls and as well to become more automated.

OCH: What innovations are at the forefront of this industry and how will they evolve?

JL: In relation to the integration of feedback of cranes to the entire plant controls, we are seeing multiple sensors, cameras and a need of feedback to users through a myriad of newly available data from the cranes. Therefore, for remotes, we are seeing an increase in requests for remotes with screens, integrated camera systems and multiple requests for programming color screens to integrate and give users feedback about items about the crane. Additionally, we are seeing motor feedback and crane feedback sensor information being uploaded to the cloud for further evaluation by crane manufacturers to receive feedback about use of the crane, remotes and how the cranes are used.

OCH: What do you see as the main challenges within this industry?

JL: Looking at the current trends, these technologies will allow for predictive maintenance for sure but also can be combined with AI predictive software to then improve future designs of cranes and the other plant/ warehouse controls. As well, these technologies will be combined with human interfaces to improve the lives of the operators, either through feedback and information systems or through combining automation technologies with user user interfaces to improve the control of cranes. For sure we will see an increase in automated crane systems using advanced vision systems, sensors and feedback loops. Given current computing power, in truth only the amount of money the end user wants to spend will be a restriction on what is really possible.

OCH: Miguel, what is your opinion of the industry at present?

MT: The Remote Radio Control (RRC) market is experiencing significant growth. While other industries may stagnate or decline over time, the use of Remote Radio Controls is expanding across an increasingly diverse range of applications.

OCH: What innovations do you have and how will this help the industry?

MT: As an inherently technological field, the Remote Radio Control (RRC) industry progresses swiftly, capitalizing on rapid advancements in microprocessors, RF radios, batteries, and more.

Modern RRCs are becoming more efficient, less susceptible to interference, and boast improved range, enhanced autonomy, and superior ergonomics. Additionally, technological developments enable the production of more customizable and costeffective products, which in turn, boosts the prevalence and market penetration of RRCs across various industries and applications.

OCH: What challenges do you foresee?

MT: One major hurdle facing the Radio Remote Control (RRC) industry is its fragmentation. This sector demands extensive expertise in various applications, knowledge that is often concentrated within certain brands and available only in specific markets. For instance, an Original Equipment Manufacturer (OEM) in the US aiming to deploy RRCs might find several local providers, yet these may lack the capability to offer solutions that meet the regulatory and support needs of other regions like Europe or Asia. As a result, the industry is moving towards consolidation through mergers and acquisitions, as well as by expanding networks. Few RRC companies can claim global reach for nearly any application requiring an RRC.

Tele Radio/ALLGON is firmly moving towards that goal currently being, by far, the RRC company with the biggest and widest network of subsidiaries in the world and rapidly expanding our product portfolio in order to become the clear choice for any company looking for a RRC solution anywhere in the world.

OCH: Brian, how much of your product range is relevant to overhead cranes and hoists?

BC: The majority of our products have ranges that serve the overhead crane and hoists industry. We can power entire crane systems with our products and offer multiple different conductor bar lines that range from 100 amps all the way to 6000 amps. Conductix-Wampfler also offers festoon systems ranging from a simple stretch wire system for jib cranes all the way up to motored festoon systems for high-speed process cranes. Our reeling product offering also varies from small single phase spring driven systems up to medium voltage systems used for gantry cranes in outdoor applications such as woodyards and ports.

As the industry has evolved so have our product offerings. In response to growing safety concerns across the industry, we added and developed products that prioritize safety and create safe maintenance zones, including features such as collision avoidance systems, bumpers, and powerguard systems. We also sell pendant and radio controls that allow operators to safely operate their cranes.

Additionally, as the industry continues to evolve with increasing automation we have developed solutions for data communication with data over power, slotted microwave guides, and fiber optic rotary joints. We expanded our radio control lines to move from simple controls to fully customizable and ethernet enabled devices.

OCH: How does ACE membership help you to penetrate that marketplace?

BC: We believe that Automation Controls and Electrification (ACE) membership enables us to be successful in the OCH market. We are passionate about serving the overhead crane industry and being involved in ACE is a great way to help move the industry forward. Membership with ACE shows our customers that we have market knowledge, but most importantly, that we are committed to the industry’s continued success. There is great conversation in the meetings with peers about changes in technology and the industry as a whole. By sharing our knowledge and expertise with other ACE members, we contribute to the creation of product standards, which help guide our end-users to safely and reliably implement our products into their manufacturing operations.

OCH: How will the rebrand to ACE help?

BC: The rebrand from ECMA to ACE is more reflective of what the group was working on and where the industry is headed. ACE reflects the move towards adding sensors, smart devices, and communication to overhead crane and wider material handling industries.

There has been an incredible amount of change in the last five years among these industries, and rebranding the organization opens the door for other companies to notice the change and become members. Additionally, there is a lot more blurring of lines for equipment between overhead cranes, Automate Storage and Retrieval Systems (AS/ RS), shuttles, and AGVs. The industry is really focused on material handling, and this can look different for many applications and the new name reflects this.

OCH: Are there any ANSI standards worth updating our readers on?

BC: ACE is currently updating and recertifying ECMA 10 and 15, Cable-less Controls (aka. Radio Controls) for general use and overhead crane specific applications. They are also updating and recertifying ECMA 35, Electrification Systems for overhead cranes and working on a new standard for industrial equipment communication. This standard will tackle practices of how to safely integrate multiple smart machines to ensure reliability and safety. ACE membership has seen rapid growth among members who are directly involved with the design, manufacture, or integration of these types of products.

OCH: Have you launched any OCH-relevant products this year that you can tell us about?

BC: We have launched two new products within the last year for the overhead crane industry. We launched the Airmark radio remote control system at the end of 2023. This product focuses on serving multiple crane applications from standard 3-motion crane all the way up to tandem control of two crane systems with standard remote system. This product comes from a conversation within ACE about how the industry is moving to reduce complexity in controls at customer sites. We have also just launched Xline, which is our new enclosed rail line. This product was designed for easy stocking with modules and toolless splices for ease of installation.

OCH: Which end-user sectors are driving demand for remote controls?

BC: Demand is being driven by two main sectors. The move towards automation has really driven the need for radio controls programmed for tailor-made applications. This customization allows equipment suppliers and customers to create tailored solutions that are intuitive for operators and easier to integrate with native ethernet communication protocols. This spans application from traditional overhead cranes in process facilities to AS/RS systems for equipment maintenance. Additionally, large end-users of general overhead cranes are increasingly looking to have a standard radio control that works across the majority of applications.These facilities often have had 2-4 different transmitter types and are looking to standardize product to help their operators safely move between different cranes.

OCH: Will a time come where every material handling application has some type of remote control or automation?

BC: I do not believe we will get to the point where all equipment will have remote controls or automation. Examples of applications that are likely to lag are maintenance jobs or overhead cranes that only see occasionally use. However, we do believe that the majority of equipment that sees regular usage will move to remote control or utilize automation. One market trend we see in the overhead crane market is moving away from backout pendant controls on budget cranes with lower usage. Radio receivers have a very low failure rate, and many equipment manufacturers and customers are moving toward just having a spare transmitter for the overhead crane.

OCH: Brett, how much of your product range is relevant to overhead cranes and hoists?

BS: HBC has an extensive portfolio of radio control systems that can be tailored to overhead crane and hoist applications. HBC offers both standard and customized solutions for a wide range of lifting applications. From handheld transmitters for standard lifting applications to customized solutions requiring state of the art fieldbus interfaces, HBC can tailor our solutions to the exact needs of the application.

OCH: How does ACE membership help you to penetrate the marketplace?

BS: Being a member of ACE allows us to stay informed about the most recent industry trends, enabling HBC to effectively advocate for our customers and promote the latest innovations and safety standards.

We consider the ability to be able to help develop and define industry standards a valuable part of being in the ACE membership group. HBC has long been involved in “raising the bar” so-to-speak, having a strong focus on safety and technology and membership in ACE only adds to our mission.

OCH: How will rebranding to ACE help?

BS: The fresh identity of the ACE rebrand will help facilitate new partnerships and opportunities with other industries and sectors, sharing expertise and resources to help drive mutual growth.

OCH: Are there any ANSI standards worth updating our readers on?

BS: A safety standard update worth mentioning would be an update to the EN13849-1, which is a safety standard for the design and integration of safety-related parts of control systems.

OCH: Have you launched any OCH-relevant products this year that you can tell us about?

BS: Available on our “bellybox” style transmitters, HBC’s radiomatic range control – to help ensure operators are always working from a safe distance. We have also recently developed radiomatic touch-to-acivate that will require “operator presence” when running the remote control to help ensure safe operation.

OCH: Which end-user sectors are driving demand for remote controls?

BS: There are a wide range of industries that are now embracing radio remote control technology. Sectors such as Steel, Aluminum, Automotive and Aerospace, who have a strong emphasis on safety, are at the forefront.

OCH: Will a time come where every material handling application has some type of remote control or automation?

BS: The industry is moving toward a future where radio remote controls will be essential for all material handling applications. These controls enhance, safety, efficiency, and flexibility across a wide range of sectors within the industry.