What truly sets us apart is our commitment to collaboration. We specialize in designing systems tailored to your specific needs. Most of our products are engineered to order, ensuring that we work closely with you to create the perfect solution for your application. Let us help you design a system that enhances efficiency and meets your unique requirements. PowerTrak cable carriers can be supplied in mild or stainless steel, molded glass-fiber reinforced nylon, or hybrid nylon and metal designed to protect your cable and hose investment within your mechanical assemblies, allowing for optimal equipment performance. Our product is a necessity for businesses who want smooth running, well maintained, long lasting industrial equipment that is operated using any form of cable or hose. PowerTrak cable carrier’s target verticals are split between heavy and harsh industrial, light industrial, and light-duty automotive and machine tool markets. Some of the appropriate markets include oil and gas, crane and hoist machinery, and steel or other material-producing mills.

Wide variety of cable carriers

Our steel E-Trak cable carrier range comes in both light and heavy industrial variants. For lighter industrial environments, PowerTrak cable carriers are available with machined bar carriers, spring-loaded removable rod carriers, aluminum channel carriers, and steel rod carriers (also available with nylon separators and/or nylon sleeves).

For heavier industrial environments, E-Trak cable carrier is available and comes with machined bar carriers, welded channel carriers (with or without horizontal dividers), vertical separators, and/or nylon sleeves to suit your application needs. E-series cable carrier is for heavy-duty applications with standard pin and ring joint fasteners, EF-series cable carrier includes reinforced outer links and bolted joint fasteners for harsh mill-duty applications. We also design custom PowerTrak cable carrier sizes and custom carriers. Please contact us to discuss your specific application.

Our hybrid G-Trak cable carrier, with molded reinforced nylon side chains and metal carriers, comes in various sizes. It can be optioned with machined bar carriers, removable rod carriers, aluminum channel carriers, steel rod carriers (with or without nylon separators or sleeves) for your application. We can also produce custom carriers with horizontal separators.

Our molded reinforced nylon GRP Trak and PowerTube cable carriers also come in multiple sizes. For GRP Trak, we accommodate cables/hoses ODs from 0.34 inches to 2.13 inches. GRP Trak cable carrier can come with flip-open retaining bars and snap-together links for easy link replacement, chain length modification, and access to cables and hoses. PowerTube cable carrier is fully enclosed for protection from dirt and debris, is available in sizes to accommodate cables/hoe ODs from 0.68 inches to 1.67 inches, and is equipped with either flange-type or scoop-type mounting brackets.

Support for numerous applications

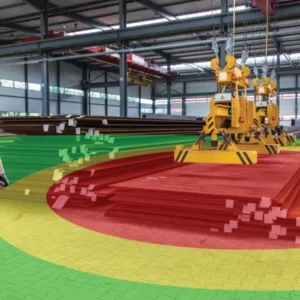

We are focused on a wide variety of applications and will consider new forms of use for our PowerTrak cable carriers. Today, applications for our cable carriers include overhead cranes, gantry cranes, rail-mounted equipment, heavier industrial moving equipment (such as piledrivers or flame cutters, directional boring machines), machine tools, oil and gas exploration equipment, stackers, and other forms of automated equipment. Our applications team is here to guide the customer through the selection process for an appropriate PowerTrak cable carrier to meet their movable machine or equipment requirements.

Compared to our competitors in the marketplace, Gleason Reel’s PowerTrak cable carrier line is more durable with high strength and exhibits smooth operation. A unique component on our steel PowerTrak cable carrier is its low-friction discs located at all joints between the movable links, allowing for quieter, smoother operation with no metal-on-metal wear.

Accessories complete the solution

PowerTrak cable carriers have optional accessories for our lighter industrial E-Trak lines.

- Our rolling carriage systems are designed to accommodate very long travel distances and heavy loads, enabling added capability for customers’ machines and equipment.

- For less demanding travel distances, we have stationary roller supports when cable or hose loads are too heavy, beyond the self-supporting capability of the cable carrier to handle by itself.

- Our sliding mounting brackets, which are required for usage with medium and high-pressure hoses, absorb any shrinkage or expansion of the hoses from hydraulic surge.

- Our chip covers, made from stainless steel, prevent any hot chips, dirt, chemical splatter from direct contact with the cable or hose, and avert mechanical damage to cables and hoses within the PowerTrak cable carrier. Additionally, we offer both anchor clamps and heavy-duty tie brackets for usage on fixed and moving ends of the PowerTrak cable carrier.

From a user’s perspective, shorter lengths of PowerTrak cable carriers come ready to install once on site. Longer sections of chain are spliced together at the installation site by following easy to follow instructions. Installation includes bolting the PowerTrak mounting brackets to one movable end and one fixed end, threading your cables or hoses through the carriers, and connecting to your power supply and movable machine or equipment.

PowerTrak cable carriers are designed to be maintenance-free. Damaged sections can be repaired quickly and easily, requiring either bolts or pins to be removed, then just replacing the affected links and/or carriers, which reduces machine downtime and does not require replacement of the entire chain.

How to order

Ordering a PowerTrak cable carrier is simple. The process first involves building a catalog number for your specific chain, per the following process.

- Select the chain size that will be suitable for the travel length required and cable/hose package it is expected to carry for your application.

- Make sure the carrier type accommodates the cable/hose package and be available on the PowerTrak cable carrier type selected.

- Select the bend radius that is equal-to or greater-than the minimum bend radius of the least flexible cable or hose.

- Determine the carrier width based on the best arrangement for the cable/hose package by following the guidelines for recommended clearances in our catalog.

At this point a catalog number is created, to be followed by the length of the PowerTrak cable carrier.

Remember to list any optional accessories, such as mounting brackets, roller supports, guide trays, or a rolling carriage. Pay close attention to the bend radius, total travel distance, maximum velocity, carrier type, and the size of carrier compartment or clearance holes that you require for the cable/hose package. Please consult with the factory on what solution will work best for your application.

A wide-range of benefits

Investment in a PowerTrak chain can save the customer considerable time and money when considering the product’s longevity and serviceability. For example, we have replaced competitor products in the field that lasted only 5 minutes to a few months before breaking and subsequently replaced with a comparable size and type of PowerTrak cable carrier. In situations like these, our applications team can swiftly respond, mocking up a PowerTrak carrier system, including a fixed roller or rolling carriage, and can be on site to supervise installation and answer any questions or concerns.

Gleason Reel is the correct choice for you. We focus on meeting your cable and hose management needs today and tomorrow by applying our innovation and expertise. For over 110 years, Gleason Reel has ensured our products will hold up well in tough environments. Our PowerTrak cable carrier solutions are customized and built to satisfy your application, while also being assembled in our hometown of Mayville, Wisconsin (USA). As part of the Hubbell family, you can count on the support of our organization.

Hubbell Incorporated was founded in 1888 by American inventor and entrepreneur, Harvey Hubbell II, who seized on the opportunities created by the commercial availability of electric power and the advent of the lightbulb. His pioneering patents like the “pull chain light socket” and “separable plug and receptacle” dramatically changed the way people lived and worked, catapulting Hubbell into an era of innovation, creating never seen before products and solutions for a rapidly growing customer base.

Today we continue our legacy of innovation as a leading manufacturer of utility and electrical solutions which enable our customers to operate critical infrastructure safely, reliably, and efficiently. We remain focused on delivering high quality, dependable products, supported by knowledgeable customer care teams, and delivered to our end-consumers through a vast network of channel partners, distributors, and retailers.