Overhead cranes are essential to efficiency and production in light to heavy industrial operations. They enable workers to lift and move all types, shapes and sizes of material, fabrications and machinery safely, quickly and precisely from place to place in ways that ground-based equipment cannot.

To make sure that overhead cranes are used safely, the operators, signalpersons and riggers who work with them must be trained how to rig loads and operate the cranes properly.

The Occupational Safety and Health Administration (OSHA) sets the safety and training requirements for workplaces in the US and holds employers responsible for making sure work sites are safe and workers are trained properly.

When it comes to the overhead cranes used in factories, warehouses and other non-construction applications, OSHA has a specific standard only for one configuration of crane. The agency addresses safety for all other types of cranes by using its General Duty clause.

OSHA requirements

OSHA’s General Industry 1910.179 standard covers cranes whose bridge and trolley both run on top of rails. Those cranes can include storage bridge cranes, gantry cranes, pulpit-operated cranes and wall-mounted cranes that can be run from a cab or from the floor.

OSHA regulates safety for all other types of non-construction overhead cranes by applying its General Duty clause, which requires employers to provide a workplace that is free of recognised hazards that could cause serious physical harm or death to employees.

To help crane users understand what the General Duty clause considers safe operation, OSHA relies on best-practice standards developed by industry experts. It also uses those standards as a measuring stick for determining whether an employer has met its obligation to provide a safe working environment.

The most common, and perhaps most influential, of those standards are produced by the American Society of Mechanical Engineers (ASME).

The ASME says the purpose of its standards is “to help prevent or minimise injury to workers and otherwise provide for the protection of life, limb and property by prescribing safety requirements”.

To do that, the ASME standards address every aspect of crane use, from inspection and maintenance to operation and training.

The ASME standards that relate to overhead cranes and lifting equipment often used in industrial applications include:

- ASME B30.2 Overhead and Gantry Cranes, which covers overhead and gantry cranes where the bridge and trolley run on top of rails, as well as cantilevered, semigantry and wall cranes.

- ASME B30.16 Overhead Hoists (Underhung), which covers hoists used on underhung cranes, including hand-operated chain hoists, as well as electrically or airpowered chain or wire-rope hoists.

- ASME B30.17 Cranes and Monorails with underhung trolley or bridge, which covers bridge cranes, monorails, wall cranes and semi-gantry cranes where the trolley or bridge end-truck wheels ride on top of the lower flange of the runway or bridge girder.

- ASME B30.10 Hooks, which covers a variety of hooks, such as clevis hooks, eye hooks, sister hooks, shank hooks and self-closing and locking hooks.

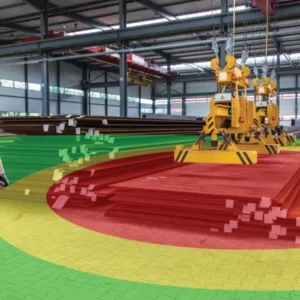

- ASME B30.20 Below-the-Hook Lifting Devices, which covers load-handling equipment like coil grabs, lifting beams, spreader beams, pallet lifters, magnets, tongs, clamps, die turners, vacuum lifters and similar equipment.

- ASME B30.9 Slings, which covers all types of slings, including alloy chain, wire-rope and synthetic webbing, among others.

Management responsible

As mentioned earlier, OSHA holds a company’s management responsible for providing a safe workplace. That responsibility includes making sure that equipment operators are trained properly and for verifying that the training was successful. That means training should be a priority supported by all levels of a company’s management.

Operator training must cover items specific to the equipment and how it is used in the application. The topics must at least cover the physical characteristics of the workplace, the crane and how it works in the specific workplace, types of loads it will handle, and the responsibilities of the crane operator, riggers, signalperson and anyone else involved in moving a load.

The training should include both classroom and hands-on instruction. Also, since most overhead crane operators are also involved in rigging loads, rigging knowledge and skill should be important parts of the training.

Testing, records and monitoring

Management must ensure that an operator passes written and practical (crane-operation) tests that prove he or she has the knowledge and skill to operate the crane(s) he or she will be operating. Further, the company should keep a formal record of the test results showing that the operator has been trained and has passed the tests and is therefore considered “qualified” according to OSHA regulations.

Until an operator has been fully trained and has passed the written and practical tests, an operator trainee may run the crane but must be always monitored by a qualified trainer who is in a safe position and can communicate with the trainee either verbally or by hand signals. Also, the trainer must not do tasks that distract him or her from monitoring the trainee.

Training options

Companies can choose to develop their own training programmes, then do the training, testing, and record-keeping themselves, or they may choose to outsource all or any part of the process to a professional training company.

That choice can depend on many factors, including how many operators need to be trained, how often new operators need to be trained, how frequently already qualified operators need to reconfirm their skills, company training staff size, training budget, as well as other considerations.

Regardless of whether a crane owner chooses to train and test operators itself or partner with outside professionals – for example, the Crane Institute of America and accredited Crane Institute Certification – making sure operators, signalpersons and riggers are trained properly and certified when required, is vital for safe and productive operation.

Copies of the ASME standards can be bought through the ASME website www.asme.org.

For more information about Crane Institute of America, visit www.craneinstitute.com.