AISTech 2024 is an opportunity for newcomers and established manufacturers to come together and discuss new practices that will benefit not only steel or steel-related companies, but the international manufacturing industry as a whole.

This year, Columbus McKinnon Corporation (CMCO) will be showcasing its next generation digital power and motion control technology, Magnetek brand IMPULSE.G+VG+ Series 5 Variable Frequency Drives (VFDs).

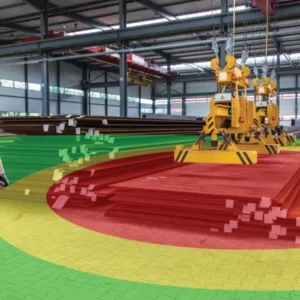

Each IMPULSE·G+/VG+ Series 5 Variable Frequency Drive comes standard with sway control and collision avoidance technology, to increase productivity and reduce the potential for injuries and equipment damage during crane or hoist operation.

“By including sway control and other new features as standard, we’re ensuring users have access to the safest, most efficient variable frequency drives that meet rising customer expectations for solutions with built-in intelligence,” said Michael Carpenter, global product manager, Automation and Controls, CMCO.

“IMPULSE·G+/VG+ Series 5 Variable Frequency Drives include more of these features, providing our customers with an industry-leading foundation for overhead cranes and hoist systems.”

Using a built-in USB port, operators can directly connect these crane drives to a PC to configure and adjust parameters, enabling easier and faster setup and adjustments. Plus, these variable frequency drives can be quickly and safely commissioned using 24 VDC voltage, decreasing the time and costs associated with inspecting, testing, and configuring these crane drives in potentially hazardous environments.

A new high-resolution keypad makes accessing and reading diagnostic information more intuitive.

Parameter menus have been restructured to ensure users have access to settings that best match their application needs without having to navigate through non-essentials. And, with new date and time stamps, fault events can be quickly identified so corrective actions can be taken and equipment returned to operation faster.

Janus

Janus AI-powered IoT cybersecurity is entering the European market, focusing on boosting the information security of the region's most crucial industries — namely medical, manufacturing, and critical infrastructure sectors.

"Europe and Taiwan have many parallels in terms of the cybersecurity challenges their strategic sectors face. Janus has been honed by such challenges in Taiwan, and I look forward to sharing how our cutting-edge capabilities can set a new standard for IoT cybersecurity in the European market," said Ares Cho, founder, Janus.

The core problem for IoT worldwide is that more automation means more network connections and therefore greater risk of cyberattacks.

According to The Economist, Taiwan produces 60% of the world's semiconductors and 90% of the most advanced ones, making cybersecurity strategically crucial, particularly as automation is increasingly leveraged. Similarly, Europe's automotive manufacturing industry contributes approximately 7% to the region's GDP, (source: McKinsey) making a strong case for robust protection of its operational technology (OT) sectors.

To address these vulnerabilities, Janus maximizes information security of a given system through several measures: by first establishing a network's behavior baseline, applying firewalls, implementing micro-segmentation, and then continuously monitoring for deviations. These provide robust IoT cybersecurity, especially for industries that have the highest impacts from disruption, such as medical, manufacturing, and critical infrastructure.

In addition, Janus' AI engine is fully self-contained, enabling it to continuously learn and optimize while avoiding the need to send data to a third party.

Cho was inspired to create Janus after witnessing numerous ransomware attacks on Taiwan's healthcare institutions in 2018 and 2019, when smart IoT solutions were widely adopted without adequate cybersecurity. To fill this gap, he developed a fully automated cybersecurity IoT solution, leveraging AI to automate processes and facilitate IT management.

His vision has grown Janus to now serve industries globally. Specific to Europe's manufacturing industry, Janus' micro-segmentation minimizes disruption of production from cyberattacks. For critical infrastructure, Janus is powerful enough to accommodate high cybersecurity standards and is customizable for specialized networks, such as power grids and EV charging stations, which are also susceptible.

Mazzella

Mazzella Lifting Technologies has signed a 51,318-square-foot industrial lease in East Chicago.

The tenant, a manufacturer and supplier of industrial lifting products, is relocating from Romeoville to a newly constructed building that offers tax savings in Indiana, according to DarwinPW.

Completed in 2022, the 249,600-square-foot property features a clear height of 32 feet, 20 exterior docks, 35 trailer parking stalls and 286 car parking spots. National Lease Advisors represented Mazzella in the lease.

Earlier in the year, Mazzella acquired John Sakach Company of St. Louis, Missouri, which has been retailing rigging equipment, wire rope and slings since 1986, whilst also providing rigging inspection and training services across the greater St. Louis region. Brands represented include Crosby, Gunnebo, Harrington, Briden-Bekaert, WireCo, Slingmax, Enerpac and Samson.

“John Sakach Company is recognised as a leader within the rigging industry because of their strong partnerships with their vendors, their dedication to educating the industry, and their commitment to the highest quality and safety standards. We are both committed to offering the highest quality and variety of products, excellent service, and leadership in education and training within the industry,” said Tony Mazzella, CEO, Mazzella.

Terry Driscoll, president, John Sakach, added: “With decades of family tradition in the rigging and lifting industry, it is only fitting that we partner with Mazzella. We are excited to join a team dedicated to constant improvement within the industry and look forward to continuing the Mazzella family legacy in the Midwest.”

Mazzella manufactures overhead cranes, but also supplies rigging products and services from more than 30 locations across North America, with around 1,000 employees.

IMS

IMS Systems, which manufactures non-contact measuring systems for the metals industry, is expanding its product portfolio through an exclusive licensing agreement with Nireco in Japan.

Nireco allows IMS to produce strip guiding systems at its facility in southwestern Pennsylvania and complement its non-contact x-ray, istope and optical gauges.

“Strip guiding systems exemplify our ongoing commitment to innovation,” said Chris Lackinger, CEO, IMS Systems. “This technologically advanced system can help manufacturers and processors of steel and aluminum strip improve quality, productivity, and delivery times. The combination of guiding systems and measuring technology creates obvious synergies within the organization.”

IMS was founded in 1980 in Heiligenhaus, Germany, near Düsseldorf. The company established a US presence in 2000 to take advantage of market opportunities throughout the United States and Canada.

It manufactures non-contact x-ray, isotope, and optical measuring systems that gauge the length, width, thickness, and other dimensions of ferrous and non-ferrous metals. IMS also offers a comprehensive line-up of Strip Guiding Systems (SGSs) to complement their measuring systems and improve Mill and Service Center productivity.

The company operates a sales, service, and production facility at its North American headquarters in Mars, PA, near Pittsburgh and its Service Center near Mobile, AL provides services to clients in the southeast of the US.

IMS strip guiding systems (SGSs) are an ideal way to mechanically correct the position of a moving strip, or to maintain the strip’s position on the machine. The advantages of using a custom SGS include achieving straight edge coils, operating at higher line speeds, and preventing product damage so you can achieve higher repeatability, better product quality, and improved productivity.

SGSs can be used on Annealing & Pickling Lines, Cold Rolling Mills, Continuous Hot Dip Galvanizing Lines, Cut-to-Length Processing Lines, Slitting Lines, Tension Leveling Lines, and on any other type of strip processing line.

An SGS can compensate for poor coil wrap quality, misalignment of rolls or machinery elements, uneven roll wear and pinch roll pressure, and inadequate tension.

Dellner Bubenzer

Dellner Bubenzer Group will exhibit (Booth 2703) at the upcoming AISTech event, which takes place May 6-9, at the Greater Columbus Convention Center in Columbus, Ohio.

We expect the theme of the importance of installing emergency brakes on cranes in the sector to endure. The host, Association for Iron & Steel Technology (AIST), is doing a good job of evolving outdated standards, with a European flavor being given to some documentation.

AISTech Technology Conference programs are developed by Technology Committee members representing iron and steel producers, their allied suppliers, and related academia. Committees focus on ironmaking, steelmaking, finishing processes, and various engineering and equipment technologies. Our exhibit will serve as a major showcase of Dellner Bubenzer brakes and Dellner Hydratech cylinders for mills and hydraulics, and accumulators for other mill applications.